Manual Wire Crimp Pull Strength Tester

Manual Wire Crimp Pull Strength Tester Specification

- Test Range

- 0 100 kgf

- Specimen Size

- 0.1 mm to 10 mm wire cross section

- Humidity

- 85% RH (operating condition)

- Temperature

- 15C 35C

- Number of Specimens

- Single specimen test

- Test Material

- Copper and Aluminium wires, Insulated/Non-insulated Terminals

- Type

- Wire Crimp Pull Strength Tester

- Material

- High-grade anodized Aluminium Alloy, Stainless Steel components

- Power

- Manual (Non-Electric)

- Power Source

- Hand Operated

- Dimension (L*W*H)

- 300 mm 200 mm 150 mm (approx.)

- Weight

- 6 kg (approx.)

- Usage

- Crimp joint strength testing

- Application

- Electrical wire harness, cable assemblies, automotive and electronics

- Finish

- Powder coated and chrome plated

- Accessory

- Supplied with interchangeable crimp jaws/clamps

- Operation Mode

- Manual lever arm or hand wheel

- Safety

- Overload protection

- Display Type

- Analog Dial Gauge

- Maintenance

- Low, easy to clean

- Calibration

- Provided with calibration certificate

- Maximum Tensile Force

- 100 kgf

- Jaw Type

- Adjustable vice or clamp

- Resolution

- 0.1 kgf

- Standards Compliance

- Meets IPC/UL/ISO crimp pull test guidelines

Manual Wire Crimp Pull Strength Tester Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 30 Days

- Main Export Market(s)

- South America, Western Europe, Eastern Europe, Middle East, Asia, North America

- Main Domestic Market

- Daman and Diu, Andaman and Nicobar Islands, North India, Tripura, Manipur, Gujarat, Central India, Meghalaya, Odisha, Chandigarh, Karnataka, Jharkhand, Dadra and Nagar Haveli, Chhattisgarh, West India, Arunachal Pradesh, Delhi, Rajasthan, Pondicherry, South India, West Bengal, Uttar Pradesh, Madhya Pradesh, East India, Jammu and Kashmir, Himachal Pradesh, Nagaland, Assam, , Bihar, Goa, Sikkim, Uttarakhand, Telangana, Lakshadweep, Andhra Pradesh, Haryana, Kerala, Punjab, Mizoram, Maharashtra, Tamil Nadu, All India

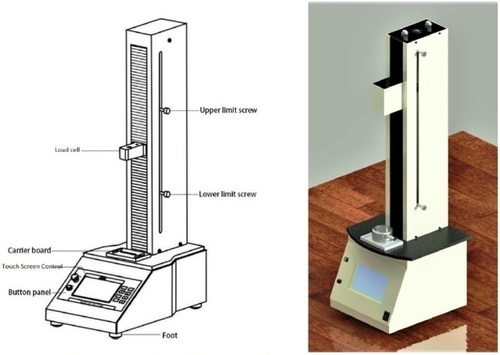

About Manual Wire Crimp Pull Strength Tester

Application:

It is an unique& economic instrument for tension/compression testing with good stability, wide application and convenient usage for manual operation. It is used for various application such as breaking strength, compression and tensile testing of Metal wire, crimp, Plastic Strip, HDPE Tape, yarn, strips & many more. Digital Force measurement devices is attached to measure the maximum breaking force in N, Kgf & Lbf..

Features:

- Simple & Hand Pressure operation,

- Able to be used with various kinds of fixtures.

- Compact design & Simple construction.

- Capacity : 500N (50Kg)

- Accuracy : 0.1N / 0.01kg / 0.02lb;

- Units : N, Kgf, Lbf

- Traveling Length : 200mm

- Data Output : RS232 communications

- Power/Air : 220 /110 V 50/60 Hz

- Weight : 20 Kg

- Dimensions : 450 x 400 x 700 mm(L x W x H)

Manual Wire Crimp Pull Strength Tester Manufacturer

Manual Wire Crimp Pull Strength Tester Supplier

Manual Wire Crimp Pull Strength Tester Exporter

Accurate Analog Measurement

Equipped with a high-resolution analog dial gauge, the tester allows for consistent and precise measurement of crimp pull strength, up to 100 kgf. The 0.1 kgf resolution ensures users can detect even minor variations in joint integrity, fulfilling quality assurance needs for sensitive wire connections.

Versatile Clamping for Various Wires

Featuring interchangeable and adjustable vice or clamp jaws, the instrument is suitable for testing a wide range of wire types and cross-sections (0.1 mm to 10 mm), including copper and aluminium wires, in insulated or non-insulated terminals. This versatility makes it a practical asset for manufacturing and assembly lines.

Manual, Safe, and Reliable Operation

The device operates manually without electricity, using a lever arm or hand wheel. Overload protection safeguards both the tester and the operator, while the powder-coated and chrome-plated finish ensures durability in demanding environments. Its low-maintenance design further adds to user convenience.

FAQs of Manual Wire Crimp Pull Strength Tester:

Q: How do I operate the Manual Wire Crimp Pull Strength Tester?

A: To use the tester, secure the wire specimen between the adjustable jaws or clamps. Choose the appropriate jaw type for the terminal size, then operate the manual lever arm or hand wheel to apply tension. The analog dial gauge displays the pull force, allowing you to observe the crimps break point or verify it meets specified strength limits.Q: What types and sizes of wires can this tester handle?

A: This device accommodates both copper and aluminium wires with cross-sectional areas ranging from 0.1 mm to 10 mm. It supports insulated and non-insulated terminals, making it suitable for electrical, automotive, and electronic cable assemblies.Q: When should calibration be performed on the tester?

A: The tester comes with a calibration certificate, but routine calibration intervals depend on usage frequency and internal quality standards. It is recommended to recalibrate at least annually or whenever accuracy is in doubt to ensure compliance with IPC, UL, and ISO guidelines.Q: Where is this tester best used?

A: Its portable and manual design makes it ideal for use in testing laboratories, production lines, quality control departments, and fieldwork within industries such as automotive, electrical manufacturing, and electronic assembly.Q: What is the process for changing the crimp jaws or clamps?

A: The tester includes interchangeable jaws or clamps, which can be swapped by loosening the locking mechanism, removing the current jaw, and installing the desired replacement. Ensure the jaws are securely fastened before use to maintain measurement safety and accuracy.Q: How does the tester ensure user safety during operation?

A: The device incorporates overload protection to prevent exceeding its maximum rated force, protecting users and maintaining instrument integrity. Its robust construction and stable base also contribute to safe usage during high-tension tests.Q: What are the main benefits of using this manual tester over electric models?

A: This tester requires no electrical power, making it easy to use in locations without readily available electricity. Its manual operation simplifies maintenance and enhances portability, while still delivering accurate, reliable results suitable for professional crimp testing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in WIRE TESTING MACHINE Category

Automatic Wire Crimp Pull Tester

Minimum Order Quantity : 1 Unit

Material : Mild Steel (Powder Coated Body)

Test Material : Crimped Wires and Terminals

Power : Other, AC 220V, 50/60Hz, 50W

Power Source : Electric

Usage : To test the pull strength of crimped wire terminals

Wire Crimp Pull Tester

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Test Material : Copper/Aluminum Wires

Power : Other, Manual

Power Source : Hand Operated

Usage : Crimp Strength Testing

Digital Wire Tension Meter

Minimum Order Quantity : 1 Unit

Material : ABS Plastic, Metal Alloy

Test Material : Metal wire, cable, string

Power : Other, 3V

Power Source : Battery Operated (2 x AA)

Usage : Measuring wire tension

Send Inquiry

Send Inquiry