Wire Elongation Tester

Wire Elongation Tester Specification

- Test Material

- Copper, Aluminum, Steel wires

- Number of Specimens

- 1 specimen at a time

- Test Range

- Up to 1000 mm elongation

- Gas Pressure

- N/A (Test is mechanical)

- Specimen Size

- 0.5 mm to 5 mm diameter wires

- Humidity

- Up to 80% RH (non-condensing)

- Temperature

- 10C to 40C operating range

- Type

- Manual/Automatic

- Material

- Stainless Steel and Mild Steel Construction

- Power

- 230 V AC, 50 Hz

- Power Source

- Electric

- Dimension (L*W*H)

- Approx. 1000 mm x 300 mm x 350 mm

- Weight

- Approx. 60 kg

- Usage

- To test the elongation of wire specimens under tensile force

- Application

- Wire Industry, Cable Manufacturing, Quality Control Labs

Wire Elongation Tester Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 10 Units, , Per Week

- Delivery Time

- 30 Days

- Main Domestic Market

- All India, North India, Daman and Diu, West Bengal, Madhya Pradesh, Jammu and Kashmir, Uttar Pradesh, Tripura, Haryana, Andaman and Nicobar Islands, Kerala, South India, Jharkhand, Central India, Uttarakhand, Dadra and Nagar Haveli, Himachal Pradesh, Chhattisgarh, Mizoram, Tamil Nadu, Assam, Pondicherry, Manipur, Maharashtra, Odisha, Sikkim, Chandigarh, Meghalaya, Punjab, Goa, Bihar, Delhi, Lakshadweep, , Nagaland, Karnataka, Gujarat, Andhra Pradesh, East India, Rajasthan, Telangana, West India, Arunachal Pradesh

About Wire Elongation Tester

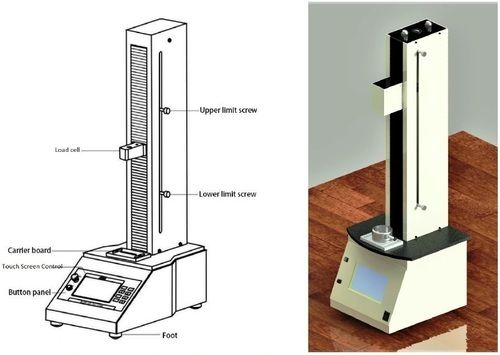

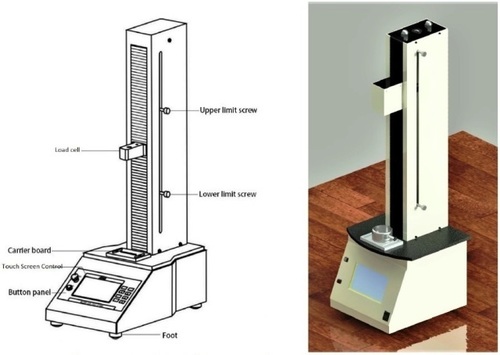

Wire Elongation Tester is unique instrument for wire elongation, with good stability, wide application and convenient usage with function of step less speed adjusting, uniform motion, converting mode between manual and automatic operation. It is used for various applications such as wire crimp force testing, Tensile Testing, Push & Pull Testing, Puncture /Piercing force, Penetration test, Measuring Strength of Glass Ampules as well as Scientific Research Institute & many more.

Features:

- Color Touch Screen Display

- PLC & Servo Drive for precise Operation.

- Simple operation, able to be used with various kinds of fixtures.

- Step less speed regulation, gear drive

- Compact design & structure with stable drive

Specifications:

- Capacity : 500N (50Kg)

- Accuracy : 0.1N / 0.01Kg/ 0.02lb

- Units : N, Kgf, Lbf

- Traveling Length : 500mm (Customized)

- Speed Selector : 0 to 500 mm/min

- Data Output : USB/ Ethernet for data saving & Network printing purpose.

- Power/Air : 220/110 V 50/60 Hz

- Weight : 75 Kg Dimensions : 400 x 400 x 1080mm(L x W x H)

High-Precision Measurement and Compliance

Engineered for reliable results, the Wire Elongation Tester offers precise elongation readings with an accuracy of 0.5 mm. The unit comes with a standard calibration certificate and complies with international testing standards, including IS, ASTM, and IEC. The optional digital display and data logging features allow for thorough documentation and quality assurance.

User-Friendly Operation and Safety

Users can easily test one sample at a time with the adjustable clamping jaws, accommodating a range of wire sizes from 0.5 mm to 5 mm. The tester offers both manual and automatic operations, built-in overload protection, and an emergency stop switch, ensuring a safe testing environment. The powder-coated body enhances durability and ease of maintenance.

Versatile Applications

This tester is ideal for conducting wire elongation tests in environments such as the wire industry, cable manufacturing facilities, and quality control laboratories. With compatibility for copper, aluminum, and steel wires, and a test range up to 1000 mm elongation, it addresses diverse material testing needs within a temperature range of 10C to 40C and up to 80% RH (non-condensing).

FAQs of Wire Elongation Tester:

Q: How is elongation measured with the Wire Elongation Tester?

A: Elongation is measured using either an analog or digital display system, depending on your configuration. The device ensures accurate elongation measurement up to 1000 mm with a precision of 0.5 mm for wire specimens under tensile force.Q: What types of wires and specimen sizes are compatible with the tester?

A: The tester supports copper, aluminum, and steel wires with diameters ranging from 0.5 mm to 5 mm. Its adjustable clamping jaws securely grip the specimen during testing for dependable results.Q: When should the calibration certificate be used or referenced?

A: The calibration certificate, supplied as standard, should be referenced before initial use and at scheduled intervals as part of your laboratorys quality assurance and compliance processes to verify measurement accuracy.Q: Where can the Wire Elongation Tester be used effectively?

A: This equipment is suitable for use in wire industry manufacturing plants, cable production companies, and quality control laboratories that require strict compliance with IS, ASTM, and IEC standards.Q: What is the testing process using this machine?

A: A single wire specimen is mounted between the adjustable jaws. The user applies tensile force via screw-driven or pneumatic mechanisms. The tester then measures the elongation until a pre-defined limit or failure point is reached.Q: How does the tester ensure operator and specimen safety?

A: Safety features include overload protection and an emergency stop switch, providing security for both operators and equipment during high-tension tests.Q: What are the main benefits of using this Wire Elongation Tester?

A: Benefits include highly accurate elongation measurements, robust safety mechanisms, compliance with international standards, user-friendly operation, and optional advanced data logging and PC interface capabilities to enhance quality control and reporting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Universal Testing Machine Category

Automatic Peel Adhesion Tester

Minimum Order Quantity : 1 , , Unit

Power Source : 220V AC, 50Hz

Material : Stainless Steel, Aluminum

Application : Industrial laboratory

Type : Other, Automatic

Peel Adhesion Tester

Minimum Order Quantity : 01 Box

Power Source : Electric

Material : Mild Steel Body with Powder Coating

Application : Testing adhesion quality of tapes, films, labels, and adhesives

Type : Other, Manual/Mechanical Peel Adhesion Tester

UTM 1T Universal Testing Machine

Price 792680 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Material : Mild Steel

Application : Laboratory

Type : Universal Testing Machine

Computerized Universal Testing Machine

Price 1900000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Material : SS

Application : Laboratory, Industrial Material Testing

Type : Other, Computerized Universal Testing Machine

Send Inquiry

Send Inquiry