Peel Adhesion Tester

Peel Adhesion Tester Specification

- Test Range

- 0.5 25 Kg

- Number of Specimens

- Single specimen per test

- Test Material

- Adhesive sheets, tapes, films

- Humidity

- Up to 80% RH

- Temperature

- Ambient to 50C

- Specimen Size

- 150 mm x 25 mm

- Type

- Manual/Mechanical Peel Adhesion Tester

- Material

- Mild Steel Body with Powder Coating

- Power

- 230 V AC, 50 Hz

- Power Source

- Electric

- Dimension (L*W*H)

- 340 mm x 220 mm x 320 mm

- Weight

- Approximately 14 Kg

- Usage

- For measurement of peel adhesion strength

- Application

- Testing adhesion quality of tapes, films, labels, and adhesives

- Finish

- Corrosion-resistant

- Scale Graduation

- 0.01 Kg

- Display

- Analog dial

- Load Application Speed

- 300 mm/min (manual)

- Safety Features

- Overload protection

- Accessories Included

- Sample cutter, extra clamps

- Mounting

- Bench-top setup

- Calibration

- Provided with calibration certificate

- Peel Angle

- 180° and 90° available

- Fixture Type

- Clamp-type for firm grip

- Standards Compliance

- ASTM D903 / IS 9840

Peel Adhesion Tester Trade Information

- Minimum Order Quantity

- 01 Box

- Supply Ability

- 10 Boxes Per Week

- Delivery Time

- 30 Days

- Main Export Market(s)

- Western Europe, Asia, Middle East, South America, North America, Africa

- Main Domestic Market

- All India, Jharkhand, Haryana, Goa, Gujarat, Rajasthan, Assam, Pondicherry, East India, South India, Odisha, Punjab, Manipur, North India, Andhra Pradesh, Telangana, Sikkim, Kerala, Jammu and Kashmir, Arunachal Pradesh, Daman and Diu, Chhattisgarh, Meghalaya, Nagaland, West India, , Uttarakhand, Central India, Karnataka, Uttar Pradesh, Chandigarh, Dadra and Nagar Haveli, Tripura, West Bengal, Maharashtra, Andaman and Nicobar Islands, Bihar, Madhya Pradesh, Mizoram, Himachal Pradesh, Tamil Nadu, Delhi, Lakshadweep

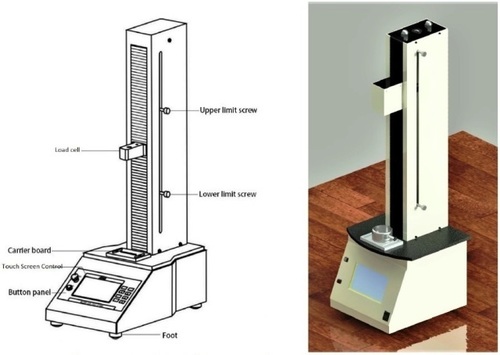

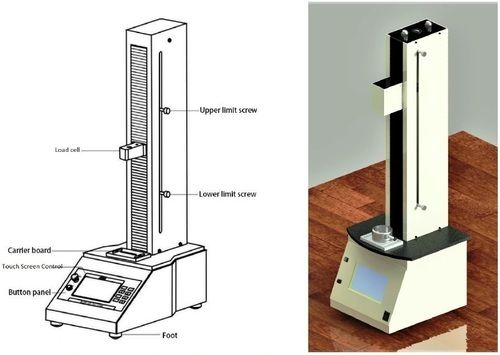

About Peel Adhesion Tester

Our Manual Peel Adhesion Strength Tester is unique & economic instrument for tension/compression testing with good stability, wide application and convenient usage for manual operation. It is used for various application such as Peeling, breaking strength, Adhesion Testing, Peel off, compression and tensile testing of Fabric, plastic, wire, crimp,yarn, strips & many more. Digital Force measurement devices are attached to measure the maximum Peel adhesive Strength & breaking force in N, Kgf &Lbf.

Features:

- Simple & Hand Pressure operation,

- Able to be used with various kinds of fixtures.

- Compact design & Simple construction.

Specifications:

- Capacity : 100N (10Kg) / 500N (50.0Kg)

- Accuracy : 0.1N / 0.01kg / 0.02lb;

- Units : N, Kgf, Lbf

- Traveling Length : 200mm / 400mm(Optional)

- Data Output : RS232 communications

- Power/Air : 220/110 V 50/60 Hz

- Weight : 20 Kg Dimensions : 450 x 400 x 700 mm(L x W x H)

peel adhesion tester, peeling strength tester, adhesive strength tester

Peel Adhesion Tester Manufacturer

Peel Adhesion Tester Supplier

Peel Adhesion Tester Exporter

Precise Measurement and Reliable Operation

This Peel Adhesion Tester offers high-precision measurement with a manual load application speed of 300 mm/min and a finely graduated analog dial. It is designed to deliver consistent results, backed by robust overload protection and a clamp-type fixture ensuring a secure specimen grip. The corrosion-resistant, powder-coated body extends longevity even in challenging environments.

Versatile Applications Across Industries

Engineered for versatility, this tester evaluates the peel adhesion of tapes, films, labels, and adhesives. With standards compliance (ASTM D903 / IS 9840), the device addresses the stringencies required in quality control labs for manufacturers, exporters, and suppliers in India and beyond.

FAQs of Peel Adhesion Tester:

Q: How does the Peel Adhesion Tester operate for different peel angles?

A: This tester allows for testing at both 180 and 90 peel angles to accommodate various industry standards and test material requirements. The sample is clamped securely, and the peeling force is measured via the analog dial as the specimen is pulled at a controlled speed.Q: What is the process for conducting a peel adhesion test using this instrument?

A: Prepare a sample of 150 mm x 25 mm, clamp it firmly using the supplied fixture, set the desired peel angle, and operate the manual mechanism to apply a steady load at 300 mm/min. The analog dial will indicate the adhesion strength, and each test is conducted with a single specimen at a time.Q: When should I recalibrate or maintain the Peel Adhesion Tester?

A: The tester comes provided with a calibration certificate. It is advisable to recalibrate periodically as per lab policy, after extensive use, or if any inconsistencies in results are noticed to ensure ongoing accuracy.Q: Where can the Peel Adhesion Tester be installed?

A: Designed as a bench-top setup, this tester can be conveniently mounted in laboratories, quality control departments, and manufacturing units. Its compact dimensions ensure it fits comfortably on standard laboratory benches.Q: What are the key benefits of using this manual/mechanical adhesion tester?

A: This tester ensures accurate, repeatable results with quick setup, compliance with international standards, and reduced downtime thanks to robust overload protection and corrosion-resistant construction. It provides essential data for optimizing adhesive quality and product performance.Q: What materials and specimens are compatible with this tester?

A: It is optimized for adhesive sheets, tapes, films, and labels that fit the specimen size requirement (150 mm x 25 mm). It accommodates tests in environments up to 80% humidity and 50C temperature.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Universal Testing Machine Category

UL94 Flammability Tester

Price 800000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Testing Flammability of Plastics and Polymers

Power Source : Electric

Weight : 120 kg

Power : Other, 220V, 50Hz, 500W

Wire Elongation Tester

Minimum Order Quantity : 1 Unit

Usage : To test the elongation of wire specimens under tensile force

Power Source : Electric

Weight : Approx. 60 kg

Power : Other, 230 V AC, 50 Hz

Automatic Pull Off Tester

Minimum Order Quantity : 1 Unit

Usage : Testing the adhesion strength of coatings

Power Source : Electric

Weight : 8 kg

Power : Other, 220V / 50Hz

Automatic Peel Adhesion Tester

Minimum Order Quantity : 1 , , Unit

Usage : Adhesive strength testing

Power Source : 220V AC, 50Hz

Weight : 45kg

Power : Other, 150W

Send Inquiry

Send Inquiry