Automatic Pull Force Tester With Touch Screen Display

Automatic Pull Force Tester With Touch Screen Display Specification

- Specimen Size

- Compatible with wire sizes 0.2 mm - 6 mm Millimeter (mm)

- Temperature

- 10C - 40C Celsius (oC)

- Humidity

- Up to 80% RH

- Test Range

- 0 - 1000 N

- Test Material

- Wires, Crimp Terminals

- Number of Specimens

- Single Specimen at a Time

- Type

- Automatic Pull Force Tester

- Material

- Mild Steel

- Power

- 220V / 50Hz, 1 Phase Volt (v)

- Power Source

- Electric

- Dimension (L*W*H)

- 500 mm x 310 mm x 200 mm Millimeter (mm)

- Weight

- Approx. 25 kg Kilograms (kg)

- Usage

- Measuring pull force of crimped terminals and wires

- Application

- Wire Harness Industry, Electronics Manufacturing, Quality Control

Automatic Pull Force Tester With Touch Screen Display Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, South America, Western Europe, Middle East, Eastern Europe, North America, Africa

- Main Domestic Market

- Odisha, Uttar Pradesh, West India, Mizoram, Chhattisgarh, North India, , South India, Kerala, Andaman and Nicobar Islands, Manipur, Punjab, Madhya Pradesh, Dadra and Nagar Haveli, Tamil Nadu, Nagaland, Central India, Rajasthan, Himachal Pradesh, Sikkim, Uttarakhand, Telangana, Goa, Tripura, Maharashtra, Delhi, Karnataka, Lakshadweep, Jammu and Kashmir, Haryana, Assam, Daman and Diu, Pondicherry, Arunachal Pradesh, Meghalaya, Gujarat, Bihar, East India, Andhra Pradesh, West Bengal, Chandigarh, Jharkhand, All India

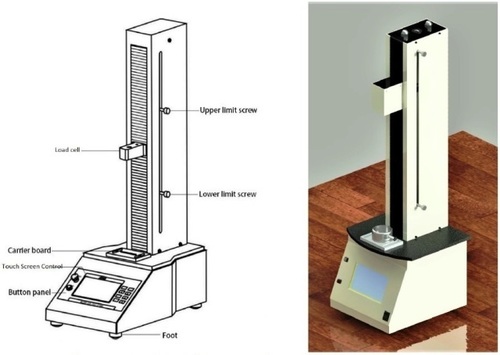

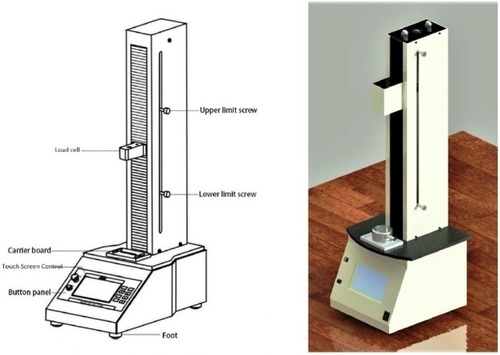

About Automatic Pull Force Tester With Touch Screen Display

Automatic Pull Force Tester is unique instrument for Cap pull out force testing with good stability, wide application and convenient usage with function of stepless speed adjusting, uniform motion, converting mode between manual and automatic operation. It is used for various applications such as Cap pull out strength Testing, Cap Force testing, Tensile Testing,Push & Pull Testing, Puncture / Piercing force, Penetration test, Measuring Strength of Glass Ampules as well as Scientific Research Institute, Bottling-Glass & Pharma Industries.

Features:

- Touch Screen Display

- PLC & Servo Drive for precise Operation.

- Simple operation, able to be used with various kinds of fixtures.

- Step less speed regulation, gear drive

- Compact design & structure with stable drive

Specifications:

- Capacity : 500N (50Kg)

- Accuracy : 0.1N / 0.01Kg/ 0.02lb

- Units : N, Kgf, Lbf

- Traveling Length : 500mm

- Speed Selector : 50 to 500 mm/min

- Data Output : Ethernet & USB option is there for saving the data in CSV/Xls format in pen drive or for network printing purpose.

- Power/Air: 220V,50Hz

- Weight: 75 Kg

- Dimensions :400 x 400 x 1080mm(L x W x H)

| Usage/Application | Laboratory |

| Capacity | As Per Required |

| Material | Mild Steel |

| Display Type | Touch Screen display Digital With Graph |

| Brand | Apple Electroniks |

| Operating Mode | Automatic |

| Voltage | 230v |

| Accuracy | 0.1N |

| Number Of Load Cells | 1 |

| Resolution | 0.1gm |

| Power | 230v |

| Weight | 45kg |

| Speed | 0-1500 mm/Min |

| External Pc Connection | No |

| Distance Between Grip | 450-800 |

| Tensile Strength | As Per Required |

| Model Name/Number | AFT |

| Number Of Columns | 1+2 |

| Product Type | Automatic Tester |

| Humidity | 50-60 |

| Load Measuring Accuracy | 0.01 |

| Warranty | 1 Year |

| Service Location | Pan India |

| Country of Origin | Made in India |

Precise Measurement and Control

This tester guarantees accuracy with its state-of-the-art microprocessor control and a 1% tolerance of full scale. The digital LCD display offers clear readouts, helping maintain quality standards in wire and crimp terminal testing. Users can easily set and monitor test parameters, enhancing consistency and reliability in laboratory and manufacturing environments.

Effortless Operation and Data Management

The automatic test cycle, coupled with an adjustable pull speed ranging from 25 to 500 mm/min, streamlines the testing process. Featuring data storage for up to 100 results and output interfaces including RS232 or USB, this device ensures seamless integration with data management systems, perfect for quality assurance teams seeking traceability.

Safety and Durability

Built with powder-coated mild steel, the tester is engineered to withstand demanding environments. Safety is prioritized with an emergency stop switch, allowing operators to halt tests instantly if needed. The instrument operates reliably within temperature ranges of 10C to 40C and humidity levels up to 80% RH, making it suitable for diverse industrial settings.

FAQs of Automatic Pull Force Tester:

Q: How does the Automatic Pull Force Tester measure pull force in wires and terminals?

A: The device utilizes a microprocessor-controlled system to apply a controlled and adjustable pull force to a single specimen, providing digital LCD readouts of the force required to separate crimped terminals and wires within the test range of 01000 N.Q: What applications is this pull force tester best suited for?

A: It is commonly used in the wire harness industry, electronics manufacturing, and quality control environments to ensure crimped connections and wire terminations meet required strength specifications.Q: When should I use the emergency stop switch?

A: The emergency stop switch should be used immediately if unsafe conditions arise during testing, or if the specimen is at risk of damage, ensuring operator safety and equipment protection.Q: Where can data from tests be stored and exported?

A: You can store up to 100 test results directly on the device. Results can be exported via RS232 or USB interfaces for further analysis and record-keeping on external computers or databases.Q: What is the process for conducting a test with this device?

A: Insert the specimen into the tester, set the required pull speed and parameters using the microprocessor interface, and initiate the automatic test cycle. The device will record and display results digitally, storing them if needed.Q: What benefits does automatic operation provide over manual testing?

A: Automatic operation enhances consistency, minimizes human error, and speeds up test cycles, ensuring repeatable results and improved productivity for quality control teams.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Universal Testing Machine Category

UL94 Flammability Tester

Price 800000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Testing Flammability of Plastics and Polymers

Material : Stainless Steel & Aluminum Alloy

Power Source : Electric

Type : Other, Vertical and Horizontal Flammability Tester

Automatic Peel Strength Tester

Minimum Order Quantity : 1 Unit

Usage : Testing Adhesion Strength

Material : Mild Steel / Stainless Steel

Power Source : Electric

Type : Other, Automatic Peel Strength Tester

Digital Pull Off Adhesion Tester

Minimum Order Quantity : 1 Unit

Usage : Measurement of Adhesion Strength

Material : Stainless Steel and Aluminum Alloy

Power Source : Rechargeable Lithium Battery

Type : Other, Digital Pull Off Adhesion Tester

UTM Tensile Testing Machine

Price 992676 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Fabric

Material : Mild Steel

Power Source : Electric

Type : UTM Tensile Testing Machine

Send Inquiry

Send Inquiry