Automatic Peel Strength Tester

Automatic Peel Strength Tester Specification

- Test Material

- Adhesive Tapes, Films, Laminates

- Port Size

- Standard 220 mm clamp

- Test Range

- Up to 50 kgf

- Number of Specimens

- 1 at a time

- Temperature

- 10 to 40

- Humidity

- Up to 95% RH

- Specimen Size

- Standard 150 mm x 25 mm

- Type

- Automatic Peel Strength Tester

- Material

- Mild Steel / Stainless Steel

- Power

- 230 V, 50 Hz, Single Phase

- Power Source

- Electric

- Dimension (L*W*H)

- 650 x 310 x 450 mm

- Weight

- 50 kg approx.

- Usage

- Testing Adhesion Strength

- Application

- Peel Strength Measurement for Adhesive Tapes, Laminates, etc.

- Data Output

- USB/Printer Interface

- Display

- Digital with Peak Hold Function

- Safety Features

- Overload Protection, Emergency Stop

- Operation Mode

- Automatic and Manual

- Measuring Unit

- Kgf / N

- Speed Control

- Variable Speed, 150 mm/min Factory Set

- Test Standard Compliance

- ASTM D903, IS 13955, IS 2770

- Accuracy

- ±1% F.S.

- Drive System

- AC Motor with Gearbox

- Load Sensor Type

- Strain Gauge Type

- Jaw Separation

- 25-300 mm adjustable

Automatic Peel Strength Tester Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 30 Days

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Asia

- Main Domestic Market

- South India, West Bengal, Delhi, Punjab, East India, Pondicherry, Karnataka, Meghalaya, Chhattisgarh, Goa, Telangana, Maharashtra, Uttar Pradesh, Andaman and Nicobar Islands, Bihar, Daman and Diu, West India, Odisha, Central India, Dadra and Nagar Haveli, Tamil Nadu, Assam, Andhra Pradesh, Lakshadweep, , Chandigarh, Gujarat, Arunachal Pradesh, Haryana, Uttarakhand, Sikkim, Nagaland, Kerala, Himachal Pradesh, Jammu and Kashmir, Manipur, Mizoram, North India, Madhya Pradesh, Tripura, Rajasthan, Jharkhand, All India

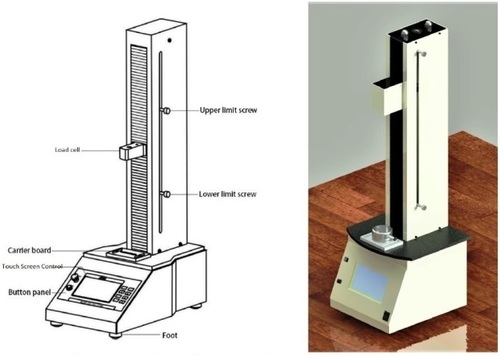

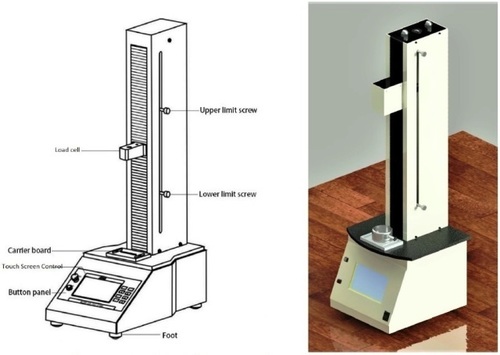

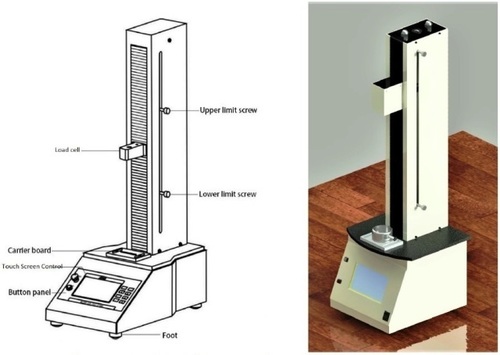

About Automatic Peel Strength Tester

Features:

- Touch Screen Display

- PLC & Servo Drive for precise Operation.

- Simple operation, able to be used with various kinds of fixtures.

- Step less speed regulation, gear drive

- Compact design & structure with stable drive

Specifications:

- Capacity : 500N (50Kg)

- Accuracy : 0.1N / 0.01Kg/ 0.02lb

- Units : N, Kgf, Lbf

- Traveling Length : 450mm

- Speed Selector : 0 to 500 mm/min

- Data Output : USB/ Ethernet for data saving & Printing purpose.

- Power/Air :220 /110 V 50/60 Hz

- Weight :75 kg : 400 x 400 x 1080 mm (L x W x H)

Peel Strength Tester, Adhesion Tester

Automatic Peel Strength Tester Manufacturer

Automatic Peel Strength TesterSupplier

Automatic Peel Strength Tester Exporter

Advanced Digital Controls and Data Output

The Automatic Peel Strength Tester comes with a clear digital display featuring peak hold functionality and variable speed control. Its user-friendly interface allows seamless data transfer through USB or printer ports, streamlining results documentation and quality assurance processes.

Versatile Testing Capabilities

This instrument is engineered to assess peel strength of a range of materials, including adhesive tapes and laminates. The adjustable jaw separation of 25300 mm and standard 220 mm clamp accommodate various specimen sizes, making it highly flexible for industry and R&D applications.

Robust Safety and Precision Engineering

Built with overload protection, emergency stop, and a strain gauge load sensor, this tester guarantees operational safety and measurement accuracy (1% F.S.). Its sturdy construction from mild steel or stainless steel ensures longevity and reliability in demanding industrial settings.

FAQs of Automatic Peel Strength Tester:

Q: How does the Automatic Peel Strength Tester improve peel strength measurement processes?

A: The tester automates the measurement process, minimizing manual intervention and ensuring consistent testing conditions. With digital controls, peak hold, adjustable speeds, and automatic or manual operation, it enhances accuracy, repeatability, and efficiency for peel strength evaluations.Q: What types of materials and specimen sizes can be tested using this instrument?

A: It is designed to test adhesive tapes, films, and laminates, supporting specimen sizes of 150 mm x 25 mm. The jaws can be adjusted from 25 mm to 300 mm, making it suitable for a wide range of industrial materials and sample dimensions.Q: When should the overload protection and emergency stop features be used during testing?

A: The overload protection engages automatically if the applied load exceeds safe limits, safeguarding both the tester and operator. The emergency stop function can be manually activated at any moment to immediately halt machine operation in case of an unforeseen issue.Q: Where is this tester commonly used, and who benefits from its features?

A: Manufacturers, laboratories, and quality assurance teams in adhesive, packaging, and material industries use this tester. Its precision, speed control, and compliance with global standards deliver valuable benefits to quality engineers and R&D professionals.Q: What is the process for conducting a peel strength test using this equipment?

A: Mount the specimen using the 220 mm clamp, select the test parameters, and choose between automatic or manual mode. The AC motor system steadily applies force while the strain gauge records measurements. Results are displayed digitally and can be exported for analysis.Q: How does variable speed control benefit the testing procedure?

A: Variable speed control, with a factory-set speed of 150 mm/min and user adjustment, allows testers to match specific requirements of different standards or materials. This flexibility helps in simulating real-world application conditions and obtaining more accurate results.Q: What are the main advantages of choosing this model for adhesion strength testing?

A: Key benefits include high measurement accuracy, compliance with major test standards, user-friendly controls, extensive safety features, data export options, and versatile sample handling. Its robust build and reliable results make it a preferred choice for industrial and research applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Universal Testing Machine Category

Automatic Penetration Force Tester

Price 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial

Type : Other, Automatic Digital Tester

Test Material : Plastic, Rubber, Medical Devices, Packaging Films

Usage : Measurement of Penetration Force in Medical and Packaging Fields

Automatic Pull Off Tester

Minimum Order Quantity : 1 Unit

Application : Paint, coating, concrete, and related material testing

Type : Other, Automatic Pull Off Tester

Test Material : Coatings, Paint, Concrete

Usage : Testing the adhesion strength of coatings

Digital Force And Elongation Tester

Minimum Order Quantity : 1 Unit

Application : Measuring Force and Elongation in Yarn and Fabric Specimens

Type : Other, Digital Force and Elongation Tester

Test Material : Yarn, Fibers, Textile and Fabric

Usage : Mechanical Testing of Materials

Digital Pull Off Adhesion Tester

Minimum Order Quantity : 1 Unit

Application : Testing adhesion of coatings on metallic and nonmetallic substrates

Type : Other, Digital Pull Off Adhesion Tester

Test Material : Paint, Coating, Plaster, Metal, Concrete

Usage : Measurement of Adhesion Strength

Send Inquiry

Send Inquiry