à¤à¥à¤¸à¥à¤¨à¤¨ वà¥à¤¦à¤°à¤¿à¤à¤ फासà¥à¤à¤¨à¥à¤¸ à¤à¥à¤¸à¥à¤à¤°

à¤à¥à¤¸à¥à¤¨à¤¨ वà¥à¤¦à¤°à¤¿à¤à¤ फासà¥à¤à¤¨à¥à¤¸ à¤à¥à¤¸à¥à¤à¤° Specification

- टेस्ट रेंज

- UV, visible light, moisture, rain, temperature, humidity

- नमूनों की संख्या

- 24

- पोर्ट का आकार

- 1/2 inch

- नमी

- Up to 98% RH

- परीक्षण सामग्री

- Fabric, polymer, coatings

- नमूना आकार

- Standard: 145 x 70 mm (custom sizes available)

- गैस का दबाव

- 0.4-0.6 MPa

- तापमान

- Ambient to 70°C (adjustable)

- टाइप करें

- मटेरियल

- Stainless Steel, Powder-coated steel body

- पावर

- पावर सोर्स

- 230V AC, 50Hz

- आयाम (एल* डब्ल्यू* एच)

- 1200 mm x 800 mm x 1800 mm

- वज़न

- Approx. 320 kg

- उपयोग

- Weathering fastness testing

- एप्लीकेशन

- Textiles, Plastics, Paints, Coatings, Rubber, Automotive components

- Control System

- Touch screen PLC controller

- Cooling System

- Integrated water cooling

- Installation

- Floor mounted

- Chamber Material

- Corrosion-resistant interior finish

- Lamp Type

- Water-cooled Xenon arc lamp

- Compliance

- Conforms to ISO, ASTM, SAE weathering standards

- Timer

- Programmable up to 9999 hours

- Irradiance Control

- Automatic, adjustable up to 1.20 W/m² at 340 nm

- Safety Features

- Over-temperature cutoff, door interlock, emergency stop

- Data Logging

- USB interface, built-in printer

- Viewing Window

- Tempered safety glass

- Operating Mode

- Continuous or cyclic exposure

- Water Spray System

- Programmable, adjustable spray frequency

à¤à¥à¤¸à¥à¤¨à¤¨ वà¥à¤¦à¤°à¤¿à¤à¤ फासà¥à¤à¤¨à¥à¤¸ à¤à¥à¤¸à¥à¤à¤° Trade Information

- Minimum Order Quantity

- 1 Unit

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- दिन

- मुख्य निर्यात बाजार

- उत्तरी अमेरिका, दक्षिण अमेरिका, पूर्वी यूरोप, पश्चिमी यूरोप, मिडल ईस्ट, एशिया, अफ्रीका

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About à¤à¥à¤¸à¥à¤¨à¤¨ वà¥à¤¦à¤°à¤¿à¤à¤ फासà¥à¤à¤¨à¥à¤¸ à¤à¥à¤¸à¥à¤à¤°

Application

The XWT is the Best & Latest Technology of Xenon Instrument which is used to determine color fastness to light, weather and light aging of various colored textiles and other materials by simulating both light and dark cycles and nature weather conditions by specimen holders and rack sprays and long-arc-xenon lamp equipped.

It uses a air- cooled xenon lamp and relevant daylight filter both are imported from USA, to simulate real and much better full spectrum sun light of outdoor, ensure the test results obtained from laboratory have a perfect correlation with outdoor application.Furthermore, the samples holder is designed with a special rotating drum to ensure each sample can obtain the same and uniform irradiance during the whole test.

It can meet with all standards requirements from different fields, it can hold 22 pieces samples,not only has spray function, but also can control the relative humidity of working room. Operator can set all required test parameters Irradiance, test time, BPT, BST etc through the touch screen, and can check its running statusat any time. All running parameters can be exported to computer directly through the USB interface.

Features:

- Xenon lamp and relevant filter imported from USA can ensure the test results have a good repeat ability and comparability.

- Special rotating-drum designed for samples holder to ensure each sample can obtain the same and uniform irradiance during the whole test.

- Irradiance energy can be accurately controlled.

- The"Sun Eye"control system can automatically compensate the change of light intensity caused by ageing or other factors.

- Can choose narrow band at 340nm or at 420nm or broadband from 300nm 400nm to control irradiance.

- Affordable air-cooled xenon lamp, the lifetime can reach 1,500 hours.

- Can choose three different filters Daylight, Window glass, Extended UV to meet different test requirements.

- The test procedures can be programmed freely; can set 9 programs and save 6 predetermined programs in one time. Every program includes up to 10 segments for setting parameters.

- Can set and control precisely and automatically the relative humidity of working room.

- Can set the cumulative energy total irradiance energy obtained by sample to finish a test procedure.

- With spray function, can set spray time and spray interval time.

- Users can easily calibrate and adjust the irradiance or the blackboard temperature by themselves.

- With High precision Pt 100 Temperature sensor. BPT black panel temperature , BST black standard temperature and working room temperature can be set and controlled precisely and automatically during the whole process

- Alarm and protection function Over temperature BPT,BST, working room, cooling water , over heating load, big error for irradiance, over standard of pure water conductivity, auto shut-down protection when opening door.

- Touch screen and user-friendly operation interface allow operator to set the test parameters and monitor all the test process easily.

- Real-time data can be collected and recorded. The incidental USB connector allow users to download the test data EXCEL format directly, achieving unattended operation.

Specifications:

- Xenon Lamp: a 1.8KW imported Xenon lamp

- Filter:Daylight filter or Windows Glass filter

- Lamp Lifetime: Around 1,500 hours-2000Hours

- Exposure Area: 2,200 cm2 (can put 22 standard samples 150x70mm)

- Adjustable Irradiance Range:

- 0.3~0.75W/m2 (Single point of control: 340nm)

- 0.5~1.35W/m2 (Single point of control: 420nm)

- 30 W/m2~90W/m2 (Full spectrum :from 300~400nm)

- Controlling Irradiance Point: 340nm or 420nm or 300~400nm (Show at the same time)

- Adjustable Black Board Temperature Range: RT+30Deg.C~90Deg.C

- Adjustable relative Humidity (RH) of Testing Chamber: 20% to 75% (Light), 50% to 95%(Dark)

- Interior Material of Chamber: Stainless steel SUS 304 material

- Exterior Material of Chamber: Powder coating

- Power : 220V 50Hz; 36A or 380VAC,50Hz, 36A.

- Weight : 200Kg.

- Dimensions : 900x900x1750mm

Xenon Weathering Fastness Tester Manufacturer

Xenon Weathering Fastness Tester Supplier

Xenon Weathering Fastness Tester Exporter

Advanced Weathering Simulation

Harnessing a water-cooled xenon arc lamp, this tester replicates sunlight and accelerated aging conditions, supporting tests for UV, visible light, rain, and humidity. Precise irradiance and temperature control, alongside adjustable spray and humidity, enable accurate simulation for industries such as textiles, automotive, paints, and plastics.

Robust Safety and Control Features

Equipped with over-temperature shutdown, emergency stop, and interlocked doors, operational safety is paramount. The touch screen PLC controller allows seamless programming of cycles, with real-time data tracking via USB and a built-in printer to ensure traceable, repeatable results.

Versatile, User-Friendly Design

Accommodating up to 24 specimens of standard or custom size, this floor-mounted tester features a corrosion-resistant chamber, integrated water cooling, and programmable timers up to 9999 hours. The large viewing window and intuitive software streamline the process for laboratories and manufacturing plants alike.

FAQs of Xenon Weathering Fastness Tester:

Q: How does the Xenon Weathering Fastness Tester simulate real-world environmental conditions?

A: The tester uses a water-cooled xenon arc lamp to generate UV and visible light, combined with a programmable water spray system for rainfall simulation, adjustable humidity (up to 98% RH), and a temperature range up to 70C. This closely replicates outdoor exposure and aging for materials like textiles, plastics, and coatings.Q: What types of materials can be tested with this equipment?

A: The Xenon Weathering Fastness Tester is suitable for a wide range of materials, including fabrics, polymers, coatings, plastics, paints, rubber, and automotive components. Its adjustable specimen holder and customizable test cycles make it ideal for diverse industry requirements.Q: When should I use the continuous versus cyclic exposure modes?

A: Continuous mode subjects samples to constant environmental exposure, ideal for endurance testing. Cyclic mode alternates between different conditions (e.g., light, humidity, spray, darkness), better reflecting natural weathering cycles. Your choice depends on the specific testing standards or real-life conditions you wish to simulate.Q: Where is the optimal location to install the testing chamber?

A: The tester is designed as a floor-mounted system with a robust stainless steel and powder-coated steel body. It should be installed in a laboratory or controlled industrial environment with sufficient space, access to power (230V, 50Hz), and water supply for optimal operation and safety.Q: What is the process for setting up and running a test?

A: Start by preparing and placing up to 24 samples in the chamber. Use the touch screen PLC to program your test parameters, including irradiance, temperature, humidity, spray frequency, and exposure duration (up to 9999 hours). Data can be logged automatically to a USB or printed for documentation, ensuring compliance with ISO, ASTM, or SAE standards.Q: How does the safety system protect users during operation?

A: The chamber features an over-temperature cutoff, an emergency stop button, and a door interlock system to prevent accidental opening during tests. The viewing window is made of tempered safety glass for both monitoring and protection.Q: What are the main benefits of using this weathering tester for quality assurance?

A: By providing accurate, accelerated weathering conditions, the tester enables manufacturers and researchers to evaluate material durability, ensure compliance with international standards, and optimize product formulations before products reach consumers, reducing costly failures and enhancing longevity.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Color Machining Testing Equipment Category

कलर प्रूफ स्टेशन

वज़न : किलोग्राम (kg)

आयाम (एल* डब्ल्यू* एच) : मिलीमीटर (mm)

पावर : , वोल्ट (v)

मूल्य की इकाई : यूनिट/यूनिट

नमी : Ambient

मटेरियल : SS

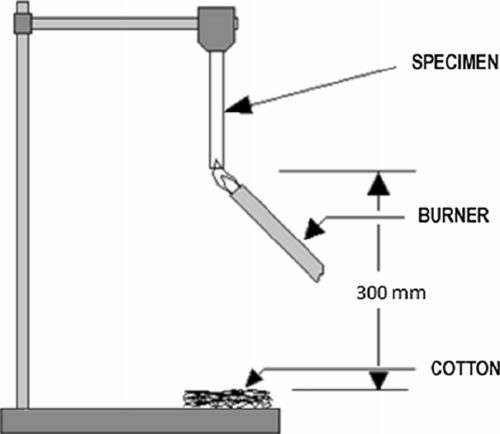

UL 94 ज्वलनशीलता परीक्षक

वज़न : Approx. 85 kg

आयाम (एल* डब्ल्यू* एच) : 1250 x 550 x 1200 mm

पावर : ,

मूल्य की इकाई : यूनिट/यूनिट

नमी : 45% – 75% RH

मटेरियल : MS

जांच भेजें

जांच भेजें